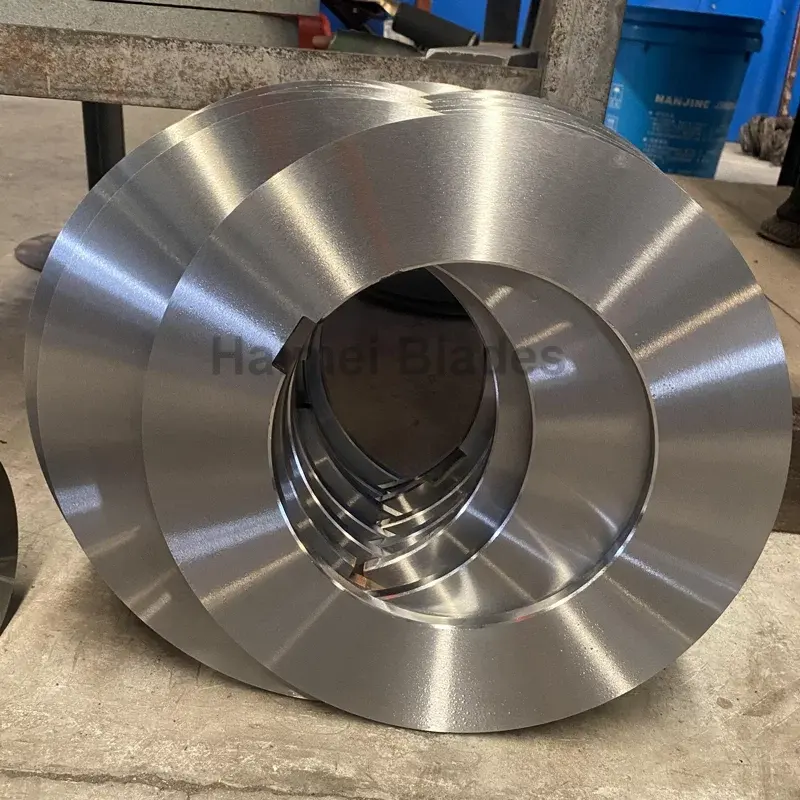

Industrial circular slitter blades are vital components in various manufacturing processes, facilitating precise cutting of materials. However, their sharp edges and the machinery involved pose inherent risks. To mitigate these risks, strict adherence to safety protocols is paramount. Here's a comprehensive guide to safety precautions when handling, installing, or changing industrial circular slitter blades:

1. Prepare with Personal Protective Equipment (PPE):

- Before engaging with circular slitter blades, ensure you're equipped with appropriate PPE. This includes safety glasses to shield eyes from debris, cut-resistant gloves to protect hands, and sturdy footwear to prevent foot injuries.

2. Thoroughly Understand Equipment and Procedures:

- Familiarize yourself with the cutting machinery and the specific blade installation procedures outlined in the manufacturer's manual. Understanding the equipment's functionality and safety features is critical before any operation.

3. Power Down and Lockout/Tagout Procedures:

- Always power off the cutting machine and follow lockout/tagout procedures before attempting any blade-related tasks. This ensures that the machinery remains inactive and prevents accidental start-ups, safeguarding against serious accidents.

4. Handle Blades with Extreme Caution:

- Circular slitter blades are razor-sharp, so handle them with utmost care. Avoid direct contact with the cutting edges, holding them only by the hub or body. Even a slight slip can result in severe cuts or lacerations.

5. Adopt Safe Lifting Techniques:

- When transporting or positioning circular slitter blades, use proper lifting techniques to prevent strain or injury. Bend at the knees, keep the back straight, and lift with the legs, distributing the weight evenly.

6. Secure the Work Area:

- Maintain a clean and organized work environment around the cutting machine. Remove any potential tripping hazards, ensure adequate lighting, and keep the area free from clutter to minimize the risk of accidents during blade handling.

7. Adhere Strictly to Manufacturer Guidelines:

- Follow the manufacturer's instructions meticulously when installing or changing circular slitter blades. Utilize the recommended tools, adhere to torque specifications, and strictly follow procedural guidelines to ensure safe and proper blade installation.

8. Conduct Thorough Inspections:

- Before installing new blades or replacing existing ones, conduct a thorough inspection of the blades, machine components, and associated hardware. Look for signs of wear, damage, or defects, and promptly address any issues to maintain operational safety.

9. Exercise Caution Around Rotating Machinery:

- Never reach into the cutting machine while the blades are in motion, even during routine maintenance tasks. Wait for the machine to come to a complete stop, and implement lockout/tagout procedures before accessing any moving parts.

10. Seek Assistance When in Doubt:

- If you encounter any uncertainties or complexities during blade handling or installation, seek guidance from experienced personnel or supervisors. Never hesitate to ask questions or request assistance to ensure tasks are performed safely and effectively.

By meticulously adhering to these safety precautions when handling, installing, or changing industrial circular slitter blades, you can mitigate risks and create a safer working environment for all personnel involved. Remember, prioritizing safety is non-negotiable when working with machinery and sharp tools.